Featuring a new collaboration with our friends at Alaska Gear Company – Husky+ Stol by Design Lightweight Aluminum Struts

Overview

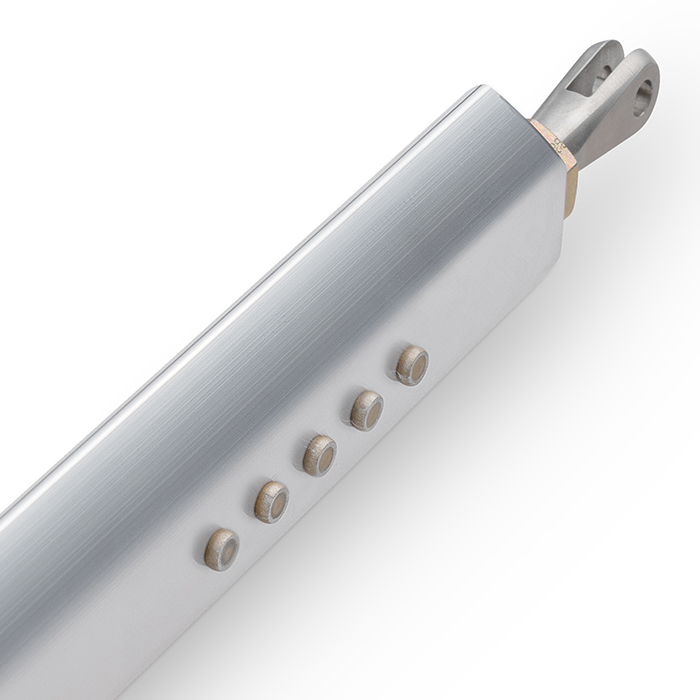

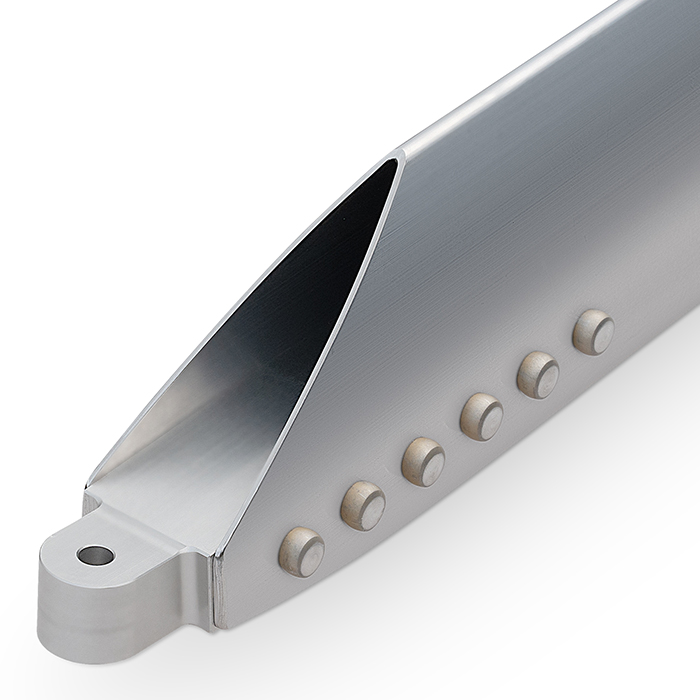

• Strut extrusions are made from 6061 aluminum. Machined end fittings are mostly made from 6061 aluminum. Lower front strut fitting has plates of titanium and aluminum incorporated into the fork fitting.

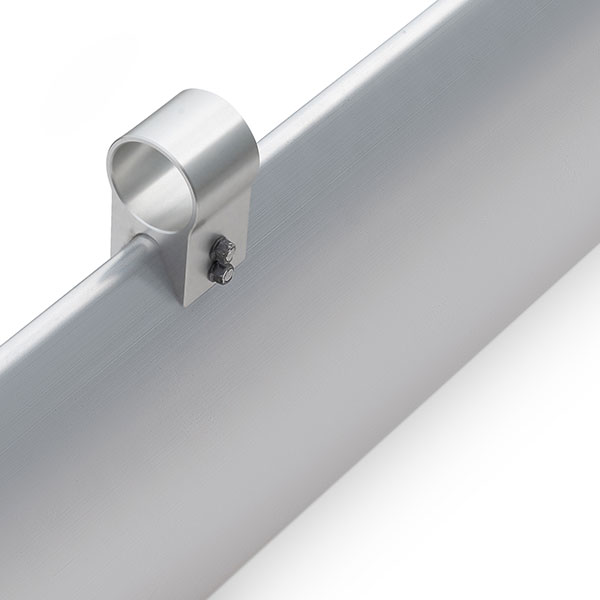

• The struts are open ended, and the end fittings are riveted into the strut.

• The strut extrusion will be bare aluminum. The end fittings are anodized aluminum and bare titanium.

• The airfoil profile of the struts is entirely different than the original steel struts.

• Front and rear steel strut clamps are included and connect to the existing jury struts. They can be sold bare metal or painted.

• The front struts are fixed and have no strut forks. The rear struts have forks that can be adjusted.

• There are left and right struts unlike our other struts.

• The approved model list is the following: Husky A-1, A-1A, A-1B, A-1C-180, A-1C-200.

Advantages over Steel Struts

• Major weight reduction close to the CG/Directly under the Wings.

• Weight reduction is 23” aft of the wing leading edge.

• Reduces 7.2 lbs. when replacing original Husky steel struts.

• Painting is not necessary.

• Strut fittings are anodized aluminum and titanium.

• The strut itself is made up of 6061 aluminum which has excellent corrosion

resistance.

$10,079.80 reach out to the factory for details 307-885-3151.